KZ75 CIP rotary spray head

Tip: click the picture to enlarge.

-

-

①CIP rotary jet tank cleaning head working principle:

Impeller is driven by cleaning fluid and drives internal reduction mechanism.The speed is constant to obtain greater impact when increasing pressure.②CIP rotary jet tank cleaning head desgin features:

*Cleaning fluid is sprayed out as a flat jet at the nozzle, and the impact force is greater, with precise layout of ball of self -rotating tank cleaning head, to achieve 360° full coverage cleaning.*Built-in deceleration structure, impeller drive, stable operation, constant speed, it takes 1-3 seconds for the ball head to rotate one circle*Operating pressure of 3-15bar

-

CIP rotary spray head /jet tank cleaning heads

Model no.: KZ75

Impeller is driven by cleaning fluid and drives internal reduction mechanism.

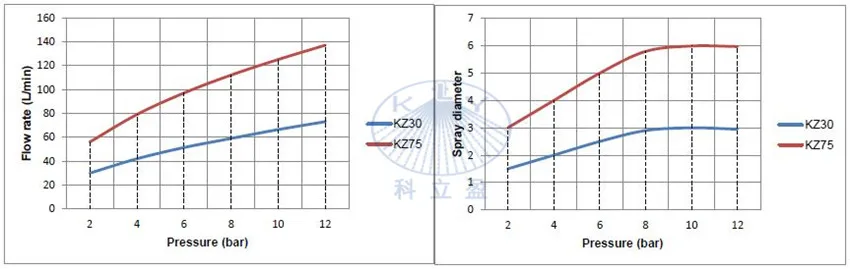

Performance Data:

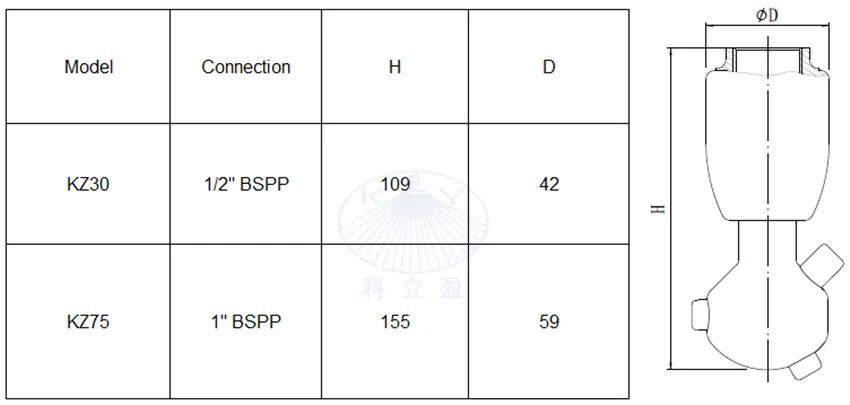

Dimensions of KZ75 360 degree spray cleaning nozzle:

Type:

|

Standard Version |

KZ30 / KZ75 |

Standard Configuration, Suitable For Working Environment Below 90 °C |

|

High Temperature Version |

KZ30-HT/KZ75-HT |

Use High Temperature Engineering Materials For 90 ° C ~ 250 ° C Working Environment |

|

Explosion-Proof Version |

KZ30-F /KZ75-F |

Use Anti-Static Materials To Avoid Static Sparks, Suited For Oils And Flammable Environments |

|

Oil Resistant Version |

KZ30-OT /KZ75-OT |

Special Engineering Materials, Strong Oil Resistance, Can Be Used For Oil Tank Cleaning |

Cleaning effect:

Industry application:

Tips

Compressed air can only be injected for a short period of time. Higher working pressures result in faster wear and smaller spray diameters, which may reduce the cleaning effect.

High impact rotary spray head

Controlled deceleration mechanism 360 degree reaction vessel cleaning high impact turbine controlled tank cleaning rotary nozzle

360 degree without dead angle small and medium-sized tank cleaning turbine structure KZ75 high impact rotary cleaning ball

Chinese

Chinese