200L Drum Cleaning Solutions

Date:2022-03-29 / Popularity:

200L industrial durm cleaning technical solution:

Chinese

Chinese

Date:2022-03-29 / Popularity:

●Improvement of the washing process: less time, less consumption and better and more reliable quality. The washing procedures can be inserted into the company quality system.

●safety of operators at the workplace.

●Need to reduce unskilled labor(KELIYING automatic washing machine : 2 to 5 minutes).

●Economic need to reduce the waste produced.

●Economic need for the reduction of the washing fluid in purchase.

●Increased washing quality.

●Increased control and measurement of production levels.

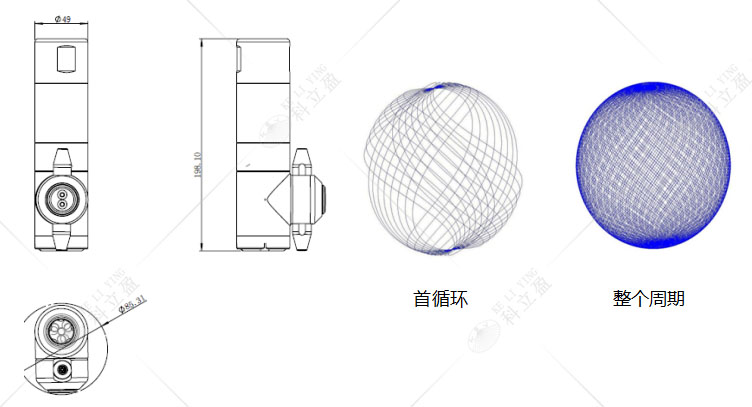

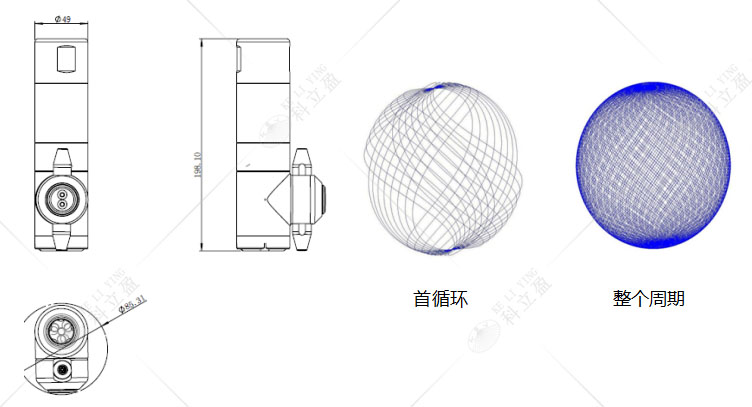

●Highest quality Tank cleaning nozzles:KELIYING offers tank cleaning nozzles with 5 to1500 bar pressure for container or tank volume of 0.1 cubic to 10000 cubic meters.

●Customized Tank Cleaning and tank washing equipment products:We offer a total solution by providing onsite surveys, analysis, design, and engineering support for tank cleaning projects.

●Washing tests and consulting:Suitable machine configuration (type of pump and recommended options) to optimize consumption and achieve the required production quota.

●Service:"On-line" support and remote assistance also thanks to step-by-step video tutorials that allow the customer to perform maintenance activities.