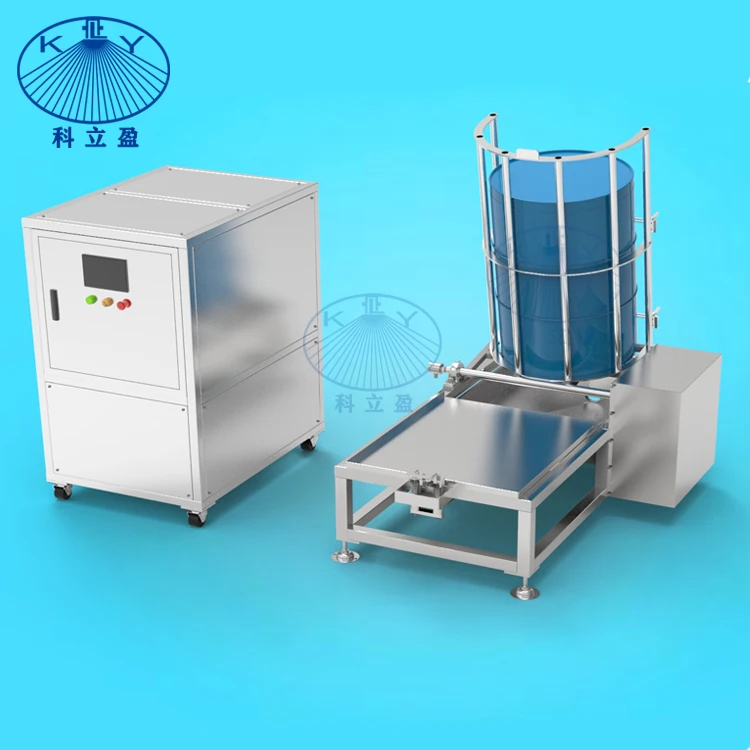

Automatic 55 Gallon Drum washer, 200L Barrel Cleaning Solution

Tip: click the picture to enlarge.

- barrel

- drum

- vats

- buckets

55 Drum Washer System Design Features :

This semi-automatic 200 liters barrel cleaning system utilizes our rotary impingement technology and is designed to blast stubborn residues from the barrel & drum in the fields of solid waste treatment, chemical industry, pharmaceutical, new energy industry, personal care and etc.. It is able to clean residues inside of the barrel in a precise and global indexing pattern. The whole cleaning operation is completed by this automatic machine and you just need the operator to monitor and control the entire cleaning process, providing some auxiliary operations if necessary.

We guaranteed that the cleaning technology ensures the entire barrel is thoroughly cleaned in the most efficient manner, utilizing the least amount of resources including time, energy, and cleaning fluid.The barrel washer comes equipped with everything you need to set up a barrel cleaning system, coming with low or high pressure cleaning nozzles according to your application.

Complete Barrel Cleaning System Structure

High Pressure Pump System

excellent water supply capacity ensures efficient operation of the barrel cleaning system.

Barrel Cleaning Working Position

a programmable logic controller(PLC) operates all of the machine functions during wash cycles to realize barrel automatic cleaning operation. This working position is designed with many structures including but not limited induction group, barrel holder and tightening handle, high pressure rotary cleaning machine, automatic barrel tilting mechanism and so on.

Drum Cleaning Technology Description

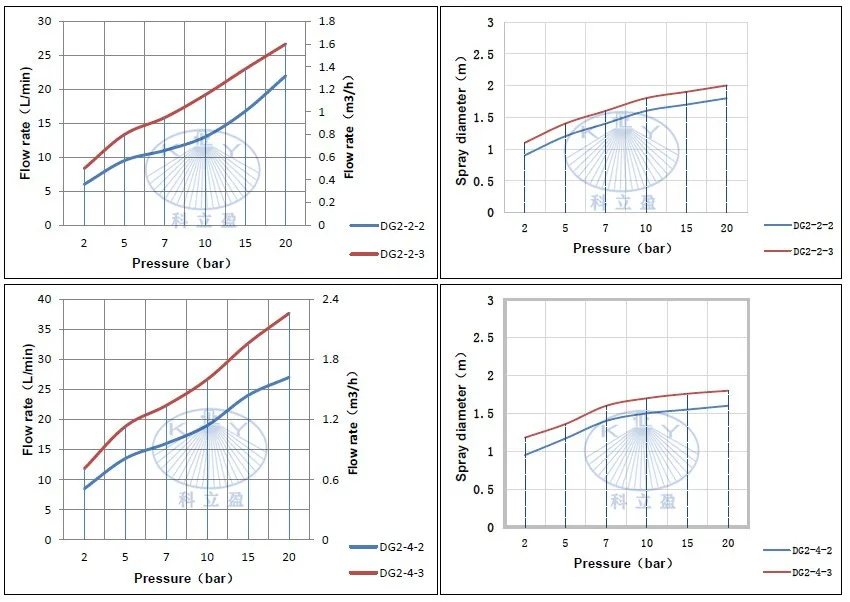

Operation demonstration: align the cleaning nozzle and put it into the bucket to be cleaned. There will be fixed jackets on both sides to fix the bucketbody. And the cleaning cycel time is 2-4 minutes (the time can be adjusted according to the situation), and operating pressure can be adjusted from 3-150 bar. Two modes can be adjusted according to the cleaning situation:

1. Low pressure cleaning modes, 3-20 bar pressure.

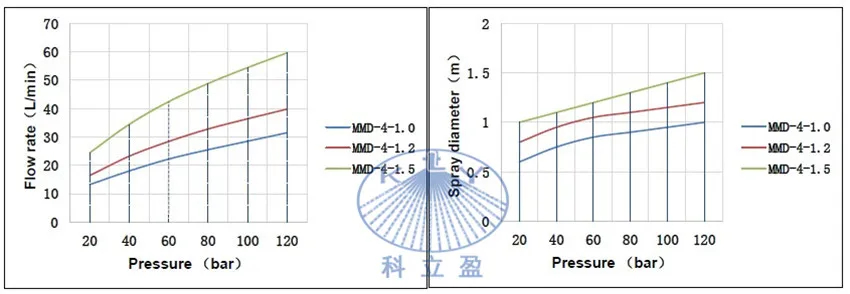

2. High-pressure cleaning modes, 80-150 bar pressure

3. Hot water detergent low pressure mode, this mode is aimed at oily barrels, first spray with detergent and then wash with 10-20 bar pressure.

4. Hot water detergent high pressure mode, this mode is aimed at petrolatum barrels, first spray with detergent and then clean with 150 bar hot water and clean water, liquid temperature is 40-50 degrees

Benefits of Barrel Washer

Fast: Clean any barrel in 2-4 minutes

Clean the entire drum, including the top and corners

Powerful: Clean a variety of residues

Affordable: A fraction of the cost of CIP tank cleaning systems

Residues:

Any and all including:

Paints, adhesives, chemicals

Petroleum products

Food and beverages products and ingredients

Pharmaceutical products and ingredients

Personal care products and ingredients products

And many more.

Common Application:

In all industries:

Photo Show :

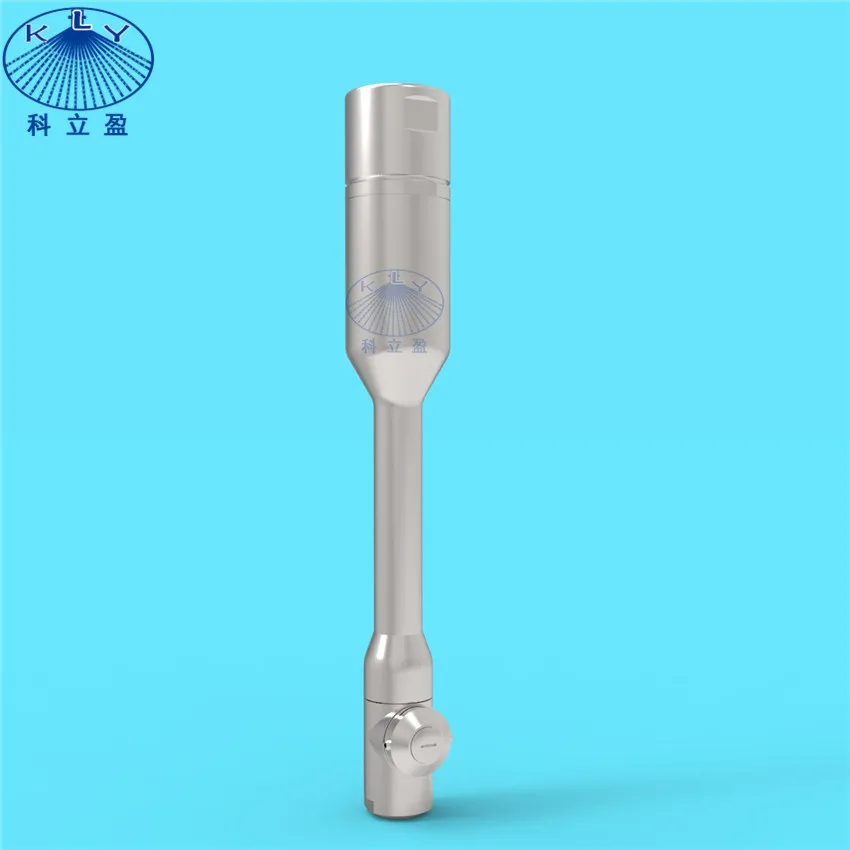

Matching Rotary washing jet head:

Performance data of barrel washing nozzle:

Application:

It is the ideal cleaning equipment for barrel washing.

In the process of cleaning, the 3D rotating high-pressure tank washer not only meets the requirements of thorough cleaning, but also reduces the consumption of resources.

Safety, eco-friendly and helps for the sustainable development.

Chinese

Chinese