Rotating tank cleaning spray nozzle

Tip: click the picture to enlarge.

KC5 high impact rotating tank cleaning nozzle,chemical tank cleaning equipment

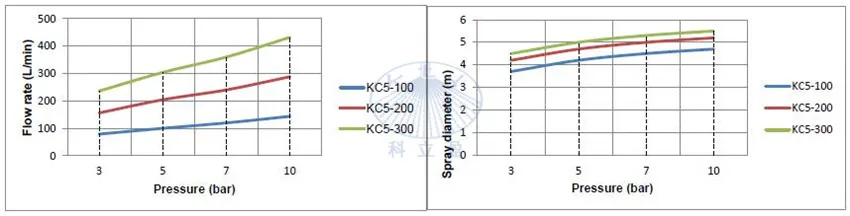

Technical data of KC5 high impact rotating tank cleaning nozzle:

| Manufacturing materials: | 316L SS | Lubrication: | Self lubrication by cleaning fluid |

| Working pressure: | 3-10 bar | Recommended pressure: | 4-7 bar |

| Maximum operating temperature: | 95°C | Maximum ambient temperature: | 140℃ |

| Cleaning angle: | 360° full coverage | Cleaning diameter: | 5m |

|

Cleaning cycle:

|

4-8 minute | Water inlet: | 3/4“FR BSSP female,1”BSPP female |

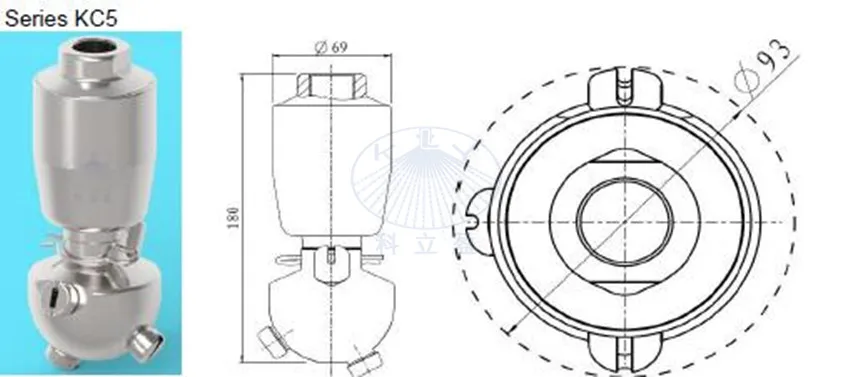

| Tank opening: | 100mm | Technical highlights: | Design of independent reducer |

| Customizable: | Explosion proof, high temperature, oil resistant | Weight: |

Tank cleaning nozzles design feature:

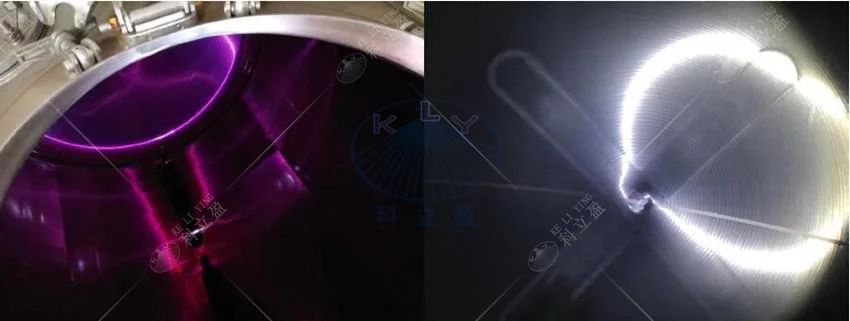

Driven by cleaning fluid, where the ball of the unit rotates at a slow speed, ensuring effective impingement of the cleaning solution on the interior walls. KC5 tank cleaning nozzle offer improved cleaning over traditional rotary spray nozzle

High impact flat jet, 360 degree spray, thoroughly clean

Internal gear reduction make it work more stable

Application:

KLY rotary tank cleaning nozzles are well suited for small to medium sized tanks, such as dairy , food, pharmaceutical, beer, chemical, industrial fermentation industry and the need for high impact cleaning occasions.

Chemical tank cleaning equipment product photos:

Performance data:

Dimensions of KC5 spray tank cleaning nozzles:

Application:

Cleaning effect:

Fittings and Workshop

Keliying has more than 30 CNC processing equipment and processing centers, as well as milling machines, drilling machines and other supporting equipment. Our company has dozens of fixed cooperative equipment manufacturers and thousands of customers, providing products with high quality and quantity throughout the year.

360 spray tank nozzle manufacturer

Chinese

Chinese